Tuesday, August 29, 2023

Successful FAT of Line 3

Since quality and production efficiency are currently the keys to success in the pharmaceutical industry, it is a great achievement for our company to complete the Factory Acceptance Test (FAT) of our new syringe line. A FAT is an important step in the manufacturing process that is performed before a machine or equipment is installed and put into operation.

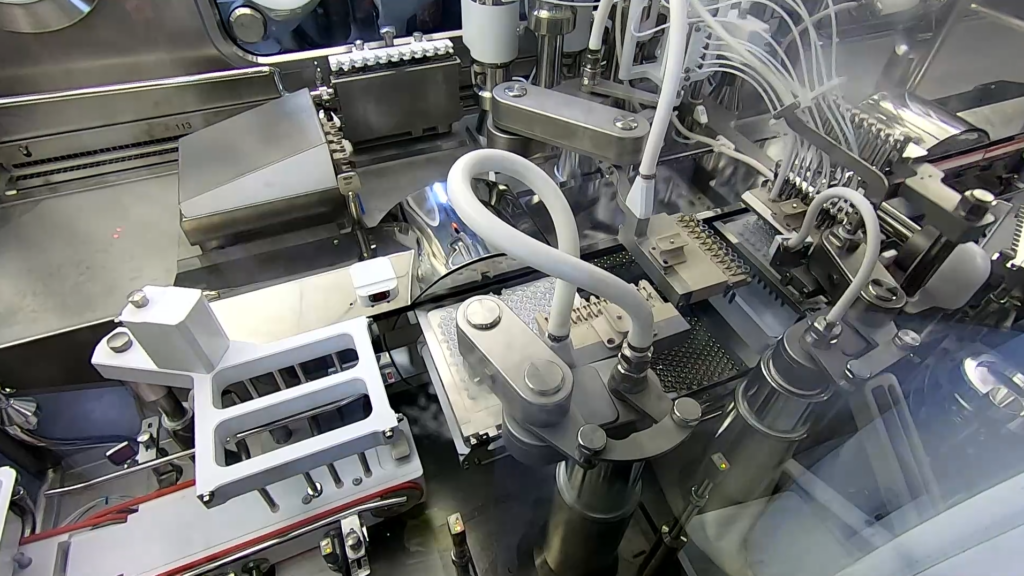

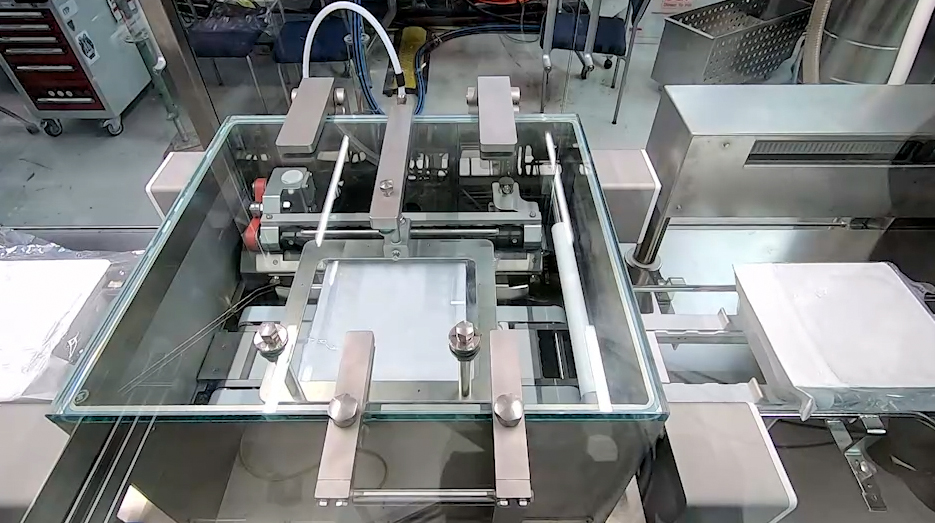

The main goal of the FAT was to verify the production procedures that will be routinely performed on individual devices. This verification was carried out with regard to a large set of processes – production preparation, the filling process and final cleaning after the production. At the same time, both the functionality of the device and the practicality and feasibility of individual actions were in focus. Both the employees of the manufacturer, Syntegon, and a team of selected employees of oncomed participated in this process to a large extent.

Filling different doses of the product was a key part of the testing. Dosing accuracy was examined as it is a fundamental factor in ensuring the quality of the final product. In addition, the precision of filling and stoppering – key aspects that ensure that each syringe is filled with the correct amount of product and properly closed – were verified.

One of the biggest successes of this testing was the one-hour operation of the line, during which it filled 101 % of the syringes. This performance points out not only the efficiency, but also the capacity of the line to work at a high level with above-standard performance.

After completing all the steps mentioned above, the FAT was evaluated as successfully completed. The line is functional and operable, the supplier can disassemble it, pack it and send it to us to Brno. Subsequently, we will begin to put the line into operation in the company.