technology

in-house technology

Our state-of-the-art technology comprises two production commercial lines dedicated to the manufacture of oncology vial injectables.

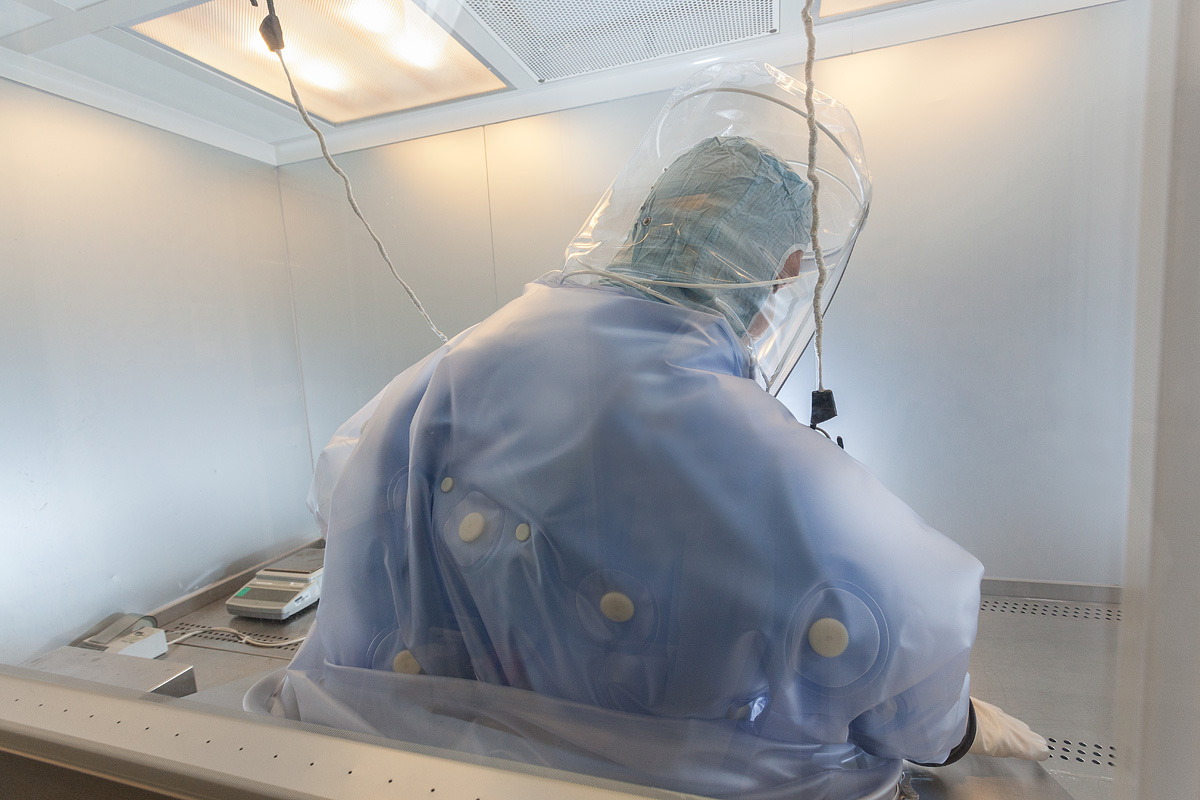

Biomolecules are processed using a single-use system technology connected to the isolator concept line.

Our leading expertise includes aseptic processing of aqueous and non-aqueous liquid, terminally sterilized, and freeze-dried products in clinical and commercial scale.

production line 1

Production line 1 uses a conventional cleanroom concept that allows us to produce batches from 10 to 1,000 litres using a stainless steel technology. Our line 1 features two freeze dryers with shelf area of 17 sqm each. The vial fill volumes range between 1 ml and 200 ml.

production line 2

Production line 2 uses an isolator concept and allows us to produce batches from 2 to 1,000 litres using a stainless steel or a single-use system technology. Our line 2 features one freeze dryer with shelf area of 12 sqm and is equipped with a dual cooling system and a solvent separator to process non-aqueous formulations. The vial fill volumes range between 0.5 ml and 100 ml.

production line 3

Production line 3 will be focused on production of syringes and cartridges. The line will use a stainless steel or a single-use system technology and its capacity will be more than 100 million syringes/cartridges per year in volumes from 1 up to 500 litres. A dual filling system will feature a time-pressure system and a peristaltic pump with a speed of 600 pcs/min. The syringe/cartridges filling volumes will range between 0.5 ml and 20 ml.

production lines comparison

Line 1Manufacturer: Gröninger Concept Clean room |

Line 2Manufacturer: IMA Concept Isolator |

Line 3 (in progress)Manufacturer: Syntegon Concept Isolator |

|---|---|---|

Formulation & Aseptic filtrationStainless steel concept

|

Formulation & Aseptic filtrationStainless steel concept Single use systemmin. batch size approx. 2 l |

FormulationStainless steel concept Single use systemmin. batch size approx. 2 l |

Filling LineVial formats 6 ml to 200 ml |

Filling LineVial formats 2 ml to 100 ml |

Filling LineSyringe and cartridge formats |

Freeze Drying2 freeze dryers, 17 sqm each |

Freeze Drying1 freeze dryer, 12 sqm |

|

Terminal Sterilization1 autoclave, 3,000 l chamber Optical InspectionSemi-automated Seidenader equipment, manual optical inspection Secondary PackagingAutomatic line, manual packaging |

Terminal Sterilization1 autoclave, 3,000 l chamber Optical InspectionSemi-automated Seidenader equipment, manual optical inspection Secondary PackagingAutomatic line, manual packaging |

Optical InspectionAutomated Syntegon equipment |

a technologically

specialized CDMO

As a specialized CDMO we bring our expertise to sterile processing and aseptic Fill & Finish of complex formulations. We master high-potent and cyto and provide access to our niche in-house technology. No additional investments of our pharmaceutical partners are needed due to the access to variable equipment sizes supported by qualified processes and transparent service offering.

We are fast, flexible and agile because we bring together advanced scientific and technical capabilities and experience, responsiveness and innovation in order to accommodate unique needs of each of our strategic partners as they navigate the dynamic drug development process.

Thanks to our authentic and brave approach rooted in our state-of-the-art technology and knowledge, you, as a partner, can dare to act with courage too and ask for advanced and highly active drug solutions. We (and our technology) will support you.

niche technologies

HPAPI handling & processing

Highly potent and toxic substances (OEB 3 – OEB 6) are handled using HIGH-TECH containment technology and processes which are OHSAS 18001 certified.

organic solvents

handling & processing

Organic solvents are handled using unique developed processes and upgraded equipment accessories which allows us to process organic solvents also in freeze-drying.

freeze-drying

Freeze-dryers are equipped with Automatic Loading and Unloading System placed in Class A. Loading directly on

pre-cooled shelves assures protection of temperature sensitive products.

sensitive products

Formulation vessels, product pipeline and filter housings are temperature controlled. Red light is used for processing light sensitive products. Nitrogen is applied in every production step.

single use system

No cross-contamination of small molecules and biomolecules thanks to custom systems of specific drug production. SUS technology to minimize losses when High Price APIs are handled.